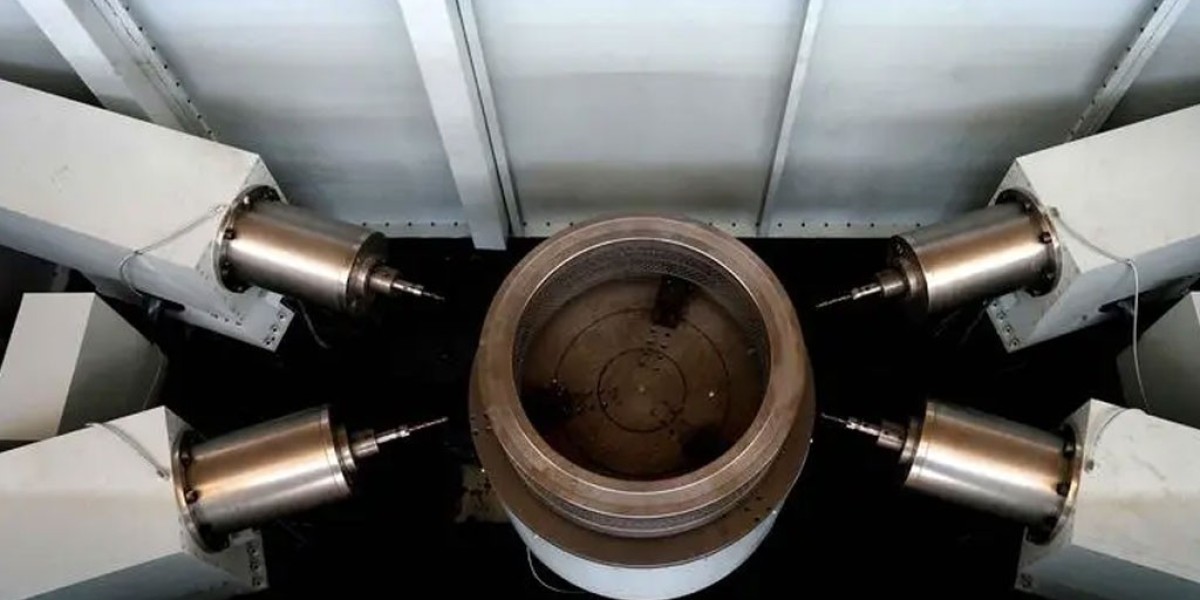

For engineers looking to optimize CNC machining, understanding the impact of part dimensions is essential. The size and geometry of the piece can affect how easily it can be held in place during the multi spindle machining process.

Larger, more cumbersome parts might require special fixturing or multiple reorientations, which can extend the machining work time. It’s crucial to design with the machining process in mind to minimize these challenges.

Balancing Complexity and Lead Time

While intricate designs might be visually appealing or functionally necessary, they can also result in longer lead times and increased costs. Every detail, curve, or hole added to a design requires additional CNC machine movements, tool changes, or even different marine machining techniques. Engineers should always weigh the benefits of design complexity against the potential increase in production time and cost.

Strategies to Expedite CNC Part Production

To ensure speedy production without compromising quality, engineers can adopt various strategies:

Preprogrammed paths: Leveraging computer numerical control programming to plan out the most efficient tool paths.

Tool selection: Using the right tool for the job can significantly reduce the time required. Whether it’s a specific drill bit for a particular hole size or a mill that can handle faster feed rates, tool selection is crucial.

Optimized design: As discussed, designing with the Oil And Gas CNC Machining process in mind can result in quicker production times. This might mean reducing the number of intricate details or designing parts that can be machined with fewer reorientations.